Just when it appears that supply chains are starting to normalize and electronic components supplies are becoming more available, the threat of a global recession is looming. Morgan Stanley analysts are forecasting a “meaningful earning recession of -16%” for 2023, although they are optimistic about recovery in 2024. A Bankrate survey of economists in July concluded there is a three in five chance of a significant economic slowdown. Other financial experts are slightly more optimistic. Goldman Sachs had forecast a 35% chance of recession in 2023 but recently revised its forecast to a 25% chance.

Besides an economic downturn and inflation, we also continue increasing trade tensions between the U.S. and E.U. with China. As the war between Russia and Ukraine also drags on, it’s created even more concerns about the availability of raw materials for components.

A recession could have a noticeable impact on the electronic component industry for the next year or two. Here’s what you can do to prepare for the likelihood of just such a recession.

Recession Impact on Electronic Component Buyers

Even without a recession, shifting market forces will make for uncertainty. If a recession does occur, electronic component buyers can expect dynamics to shift. Some of the shifts may evolve slowly, while others may be quite sudden. Look for the following trends in sales and the supply chain:

Reduced Consumer Spending

As prices rise and wages stagnate, consumer confidence erodes. This can lead to reduced spending, especially on non-essential and high-priced items. The aerospace and automotive industries have been particularly hard hit in the past due to rapidly changing consumer demand.

Decreasing Production

Many suppliers will be forced to decrease production due to reduced demand. This can make it more difficult to get the components you need at an affordable price. Production slowdowns mean less immediately available inventory, creating longer lead times and challenges to meet orders.

In past recessions, we also saw many smaller suppliers shut their doors. As demand slows, many niche providers become more vulnerable as consumer buying habits change abruptly.

Supply Chain Disruptions

Financial pressures, plant closures, bankruptcies, and staff reductions can also impact availability. It will be crucial to identify potential supply chain problems early to avoid significant problems.

Supply-Demand Imbalances

These economic conditions create supply-demand imbalances. This can create periods of severe component shortages and add to inflationary pricing.

Preparing for a Recession

In figuring out how you prepare for a recession, many of the strategies focus on risk reduction. This includes getting closer to your clients and suppliers to better plan, keeping an eye on supplier health, and more precise inventory management.

So, let’s look at how to prepare for a recession in the electronic components industry.

Demand Forecasting

Communication with clients and suppliers will be crucial to gauge demand amid a recession. While historical data can help, you need to watch emerging trends carefully for signs of deviation from the norm.

Information will be key, so make sure to focus attention on marketplace forces and refine your demand forecasting and planning to reflect potential upheaval.

Scenario Planning

To prepare for a recession, it helps to game plan different scenarios that may occur with increasing levels of severity. This enables you to think through best-case, worst-case, and in-between situations and have a plan in place — rather than waiting until the situation develops and you’re under pressure.

As you see economic changes occurring, you can more readily make agile adjustments to remain competitive and profitable based on your plan.

Supplier Evaluation

You will want to evaluate the financial health of your suppliers. Even those with strong track records may be subject to new financial pressures that can impact your business. Keep an eye on credit ratings and industry news about your key suppliers and look for any potential red flags.

As part of your game plan to prepare for a recession, you should also envision which suppliers are most vulnerable and discuss what you will do if they are no longer viable sources.

Diversify Your Supply Chain

Take proactive steps to diversify your supply chain and see what alternatives are available. Diversification reduces your risk, but if you wait until your current suppliers cannot fulfill orders, it may be too late. You may be forced to accept poor terms, higher pricing, or expedited shipping charges. By creating a relationship now with additional suppliers just in case, you can be ready.

Distributors like Sensible Micro Corporation can be a key asset to help you find alternate sources.

Inventory Management

If a recession occurs, inventory management will be essential. It may be necessary to embrace lean practices to both reduce inventory and make sure you have safety stock for critical electronic components.

This is a delicate balancing act.

At the same time, you may wind up with excess components as demand shifts. This may require liquidation to avoid tying up capital in components that are no longer needed. Sensible Micro Corporation can also help you move unused stock and find buyers.

Improve Your WA and Inspection Process

If a recession disrupts your suppliers, it may force you to work with new vendors. While you want to do your due diligence, you also need to be on guard for an increase in counterfeit and substandard parts on the market. Even for reputable suppliers, counterfeits can be introduced upstream and slip through the cracks.

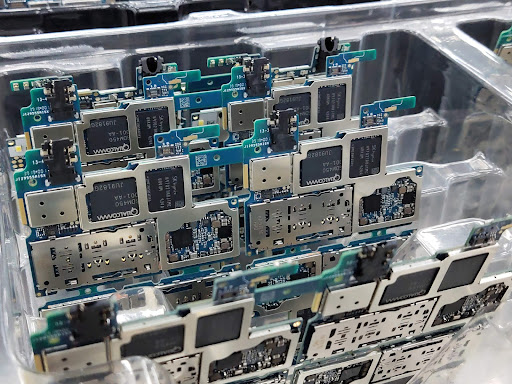

Where you buy your parts can make a significant difference. Sensible Micro has an in-house testing and validation lab to assure parts will meet your standards and specifications. Every order receives a 72-point confirmation process to assure quality.

Sensible Micro Can Help

We have franchised lines with OEMs throughout the electronic components industry. We carry a large volume of in-stock inventory and have a network of vetted suppliers that can serve as alternative sources to help you diversify your supply chain or overcome sudden disruptions.

How to prepare for a recession requires being proactive. Talk to the experts at Sensible Micro today and let’s discuss your options. Get in touch with us today.