Supply chains today have steadily grown more global, more fragmented, and faster-moving. All of these factors have introduced increased risks. A recent survey of several thousand shipping customers revealed that 76% of them experienced supply chain disruptions that delayed their business operations within the past year, and 22% reported over 20 disruptive incidents in that time.

For Original Equipment Manufacturers (OEMs), the volatility of the supply chain means one thing above all: quality can’t be left to chance. Even a single faulty or counterfeit part can derail production, damage a brand’s reputation, introduce unavoidable delays, and even create costly recalls. Counterfeit products are a growing problem across industries, with a huge impact on the global market. Fake products account for about 3.3% of global trade, with an estimated value of over $500 billion.

Component testing is swiftly becoming a non-negotiable element of modern sourcing strategies. OEMs can opt for thorough testing and inspection services to verify component authenticity, ensure product functionality, and also safeguard the reliability of every component that enters their production lines. It’s an investment in quality and peace of mind that protects your brand reputation.

Why Component Testing Matters

Component testing reduces risk at every level of the supply chain. Counterfeits and substandard components are a known threat in electronics manufacturing. According to the Semiconductor Industry Association, the global market loses $7.5 billion per year to counterfeit semiconductors. And these aren’t always obvious fakes. Sophisticated counterfeiters often re-mark used or substandard parts, which can make them hard to spot without proper inspection in an advanced lab.

A proactive approach to testing makes a difference. A battery of relevant visual, chemical, and electronic or mechanical tests can help to ensure each component is both authentic and able to meet required performance and safety standards. Testing gives OEMs confidence in quality even while managing multiple suppliers, rapid design cycles, and global production networks.

Comprehensive Testing and Inspection Services

A robust testing strategy uses multiple inspection methods, each designed to catch different types of defects or fraud. At Sensible Micro, our testing and inspection services cover a full spectrum of approaches to ensure no weak link goes unnoticed.

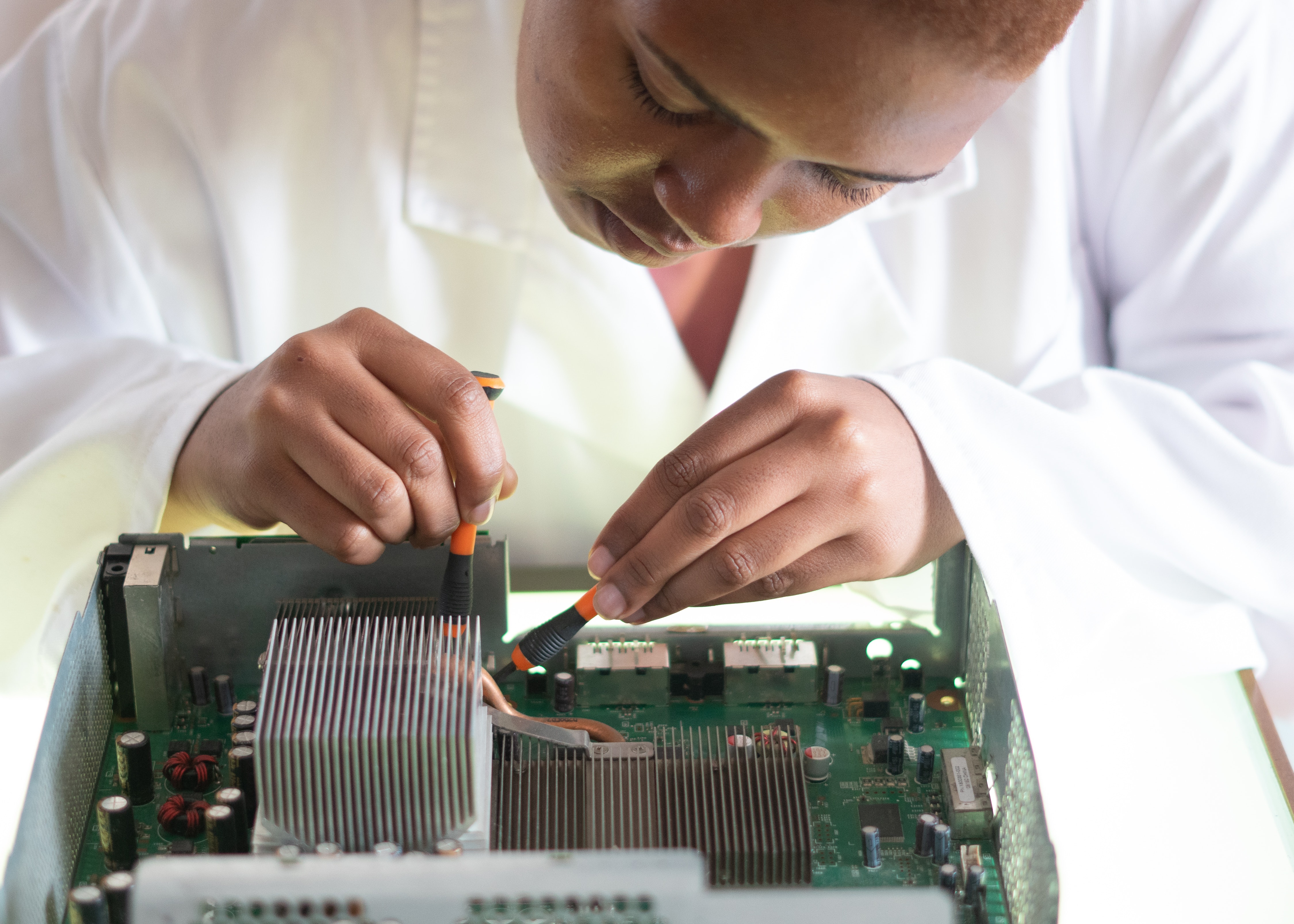

Visual Inspections

The first line of defense is a thorough visual inspection. Technicians look for telltale signs of counterfeit parts like mismatched markings, irregular packaging, or signs of prior use. While it might seem simple, expert visual inspections remain one of the most effective ways to detect counterfeit components early.

Our team combines high-resolution imaging with trained expertise to spot discrepancies that untrained eyes would miss. Visual inspections also include checking manufacturer labels, date codes, and moisture sensitivity indicators for accuracy and condition.

X-Ray and XRF Analysis

Counterfeiters can replicate packaging, but it’s not easy to fake what’s inside. This makes internal imaging an indispensable capability for authenticating components in a testing lab.

Our Creative Electron TruView Prime system provides high-resolution insight into a component’s internal structure. With reel-to-reel capability, we can perform 100% X-ray inspection of parts on reels. Facial recognition software compares die size, die frame, die location, and wire bond placement against known-good samples. These insights help us detect inconsistencies that could indicate tampering or damage. It also confirms the presence of die, checks for intact wire bonds, and can flag potential ESD damage.

XRF analysis is another valuable capability for determining the physical makeup of the component. Our Bruker S1 XRF analyzer breaks down the elemental composition of component leads. This helps verify whether plating materials match the manufacturer’s specifications and ensures compliance with RoHS requirements when needed.

Together, these methods help ensure every part meets expectations, inside and out.

Electrical Testing

Of course, visual checks aren’t enough, even if they can reveal internal structures. Performance has to be proven. Electrical testing validates that components meet original specifications for function and performance. This can involve checking resistance values, verifying logic outputs, or performing curve tracing. In any case, electrical testing acts to make sure the part is both genuine and fully operational.

This level of testing has the most value in high-reliability sectors like aerospace, medical devices, or automotive electronics, where even minor failures can have serious consequences.

Advanced Capabilities

Beyond these core methods, the advanced Sensible Micro testing lab offers a range of component testing capabilities that address today’s evolving threats and customer needs. We handle everything from decapsulation and die inspection to chemical analysis, and our approach is always designed to keep pace with increasingly sophisticated counterfeiting methods.

How Sensible Micro Supports Your Quality Goals

Your supply chain success depends on consistent, proven quality. The Sensible Micro team has built our testing and inspection capabilities to meet or exceed industry standards. Our in-house lab offers IDEA-STD-1010-B inspections, high-powered microscopy, and X-ray analysis, all performed by experienced, certified professionals.

We also understand that testing doesn’t happen in isolation! Our services integrate seamlessly into your broader supply chain sourcing strategies. We help OEMs with proactive obsolescence management so that substitute or replacement parts are equally vetted and reliable as legacy products move through their lifecycle. Through detailed BOM analysis, we help you spot potential risk areas early and make sure each component source meets your quality requirements.

A guarantee of quality is the foundation of any resilient, responsive supply chain. Your investment in thorough component testing means fewer surprises or disruptions and greater confidence in the products you deliver to customers. Learn more about how our testing and inspection services can strengthen your supply chain or find the parts you need and get a quote!