High-power optical examinations are a versatile, go-to technique that’s the workhorse of the inspection lab. Microscopy is critical to detecting material flaws, locating failure mechanisms, and comparing with a golden sample to identify counterfeit components.

Because it is a non-destructive technique, it is also easily combined with many other tests in a comprehensive component inspection. Buyers can be proactive in protecting their investments from substandard, suspect, or inauthentic components by always opting for high-power microscopy as an element of all standard inspections.

What is High-Power Microscopy?

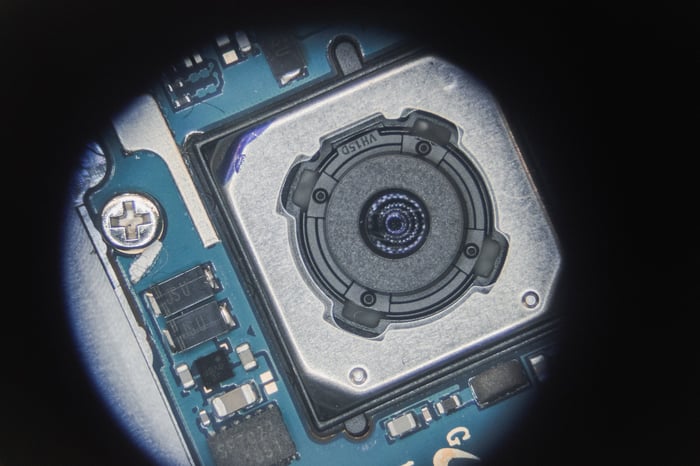

The term refers to a visual inspection with a high level of magnification. The generally accepted standard for “high-power” microscopy is an optical examination that uses a magnification range of 50X or more (potentially all the way up to the limitations of visible light at 2000X).

Optical microscopy has the advantage of simple preparation and no requirement for any sort of special environment. Testing is performed by placing the component under the optical microscope with appropriate lighting. What is revealed will depend upon the inspector’s specialization and level of expertise.

What Are Some Applications of High-Power Microscopy?

- Quality Assurance Inspections: A visual inspection is a cornerstone of QA for parts at every stage of the supply chain, from the factory to distribution channels. At Sensible Micro, we perform all external visual inspections in accordance with IDEA-STD-1010, a 72-point visual confirmation that’s preferred in the electronic components industry for its rigor.

- Failure Analysis: It’s difficult or impossible to diagnose and locate precise failure mechanisms by the eye in an integrated circuit or other electronic components. Parts have become so fine and so small that intense magnification is the only reliable way to achieve a clear view of the details necessary to assess the construction, workmanship, and faults in a modern IC.

- Counterfeit Component Detection: Counterfeit ICs have reached a point where they can be highly passable as genuine components, so it will often take more than a simple eye test to detect them. High-power microscopy enables the inspector to carefully examine a surface for fine details such as component leads, internal die markings, and wired bond integrity.

High-Power Microscopy Capabilities at Sensible Micro

Our IDEA-ICE-3000 certified inspectors at Sensible Micro incorporate high-power microscopy into all General Counterfeit Avoidance Tests and IDEA-STD-1010-B inspections, revealing high-resolution details that would be imperceptible to the eye. This proven visual inspection protocol is cited in AS5553 and used by the most quality-focused OEMs and distributors in the industry.

With our fully-motorized Keyence VHX-7000 stage, we have advanced magnification capabilities ranging from 20X to 1000X. We use microscopy to generate high-resolution imagery and depth-of-field photography — crucial elements of our surface and lead inspections. High-power microscopy and marking permanency tests are included in every inspection, protecting your investment and verifying component quality for total peace of mind.

Sensible Micro is able to support custom flow-down inspections or test plans, direct from your quality engineering initiatives. If you need to develop a GCAT plan that supports your application end-use requirements, we’re ready to help.

Request a sample IDEA-1010 or GCAT report to see what our visual component inspection and lab reports look like here.