UNMATCHED QUALITY ASSURANCE

Industry-Leading Testing & Inspection Capabilities

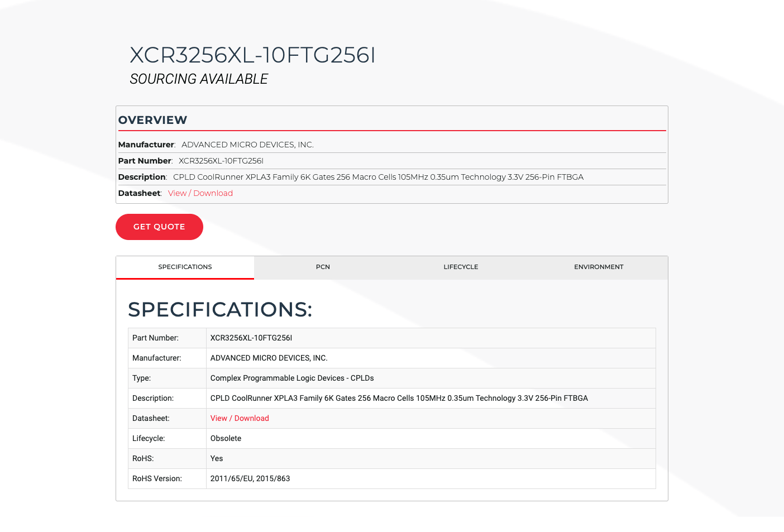

Ensure every component meets your high standards with Sensible Micro’s state-of-the-art testing and inspection services. As an AS6081, IDEA-QMS-9090 and ICE-3000 certified company, our lab is equipped to handle everything from basic visual checks to complex analytical tests, ensuring quality, authenticity, and compliance every step of the way.

Comprehensive Capabilities For Testing Electronic Components

Quality is our highest priority. We show that commitment by housing a technically-advanced anti-counterfeit inspection lab right inside the Sensible Micro facility.

Our Electronic Component Testing Capabilities

Customers also have the option to utilize our in-house lab facility. Depending on end-use application and product type, Sensible Micro can support a custom flow-down inspection or test plan, straight from your quality engineering initiatives. Don’t have one? Sensible Micro can help create a General Counterfeit Avoidance Test (GCAT) plan that supports your application end-use requirements.

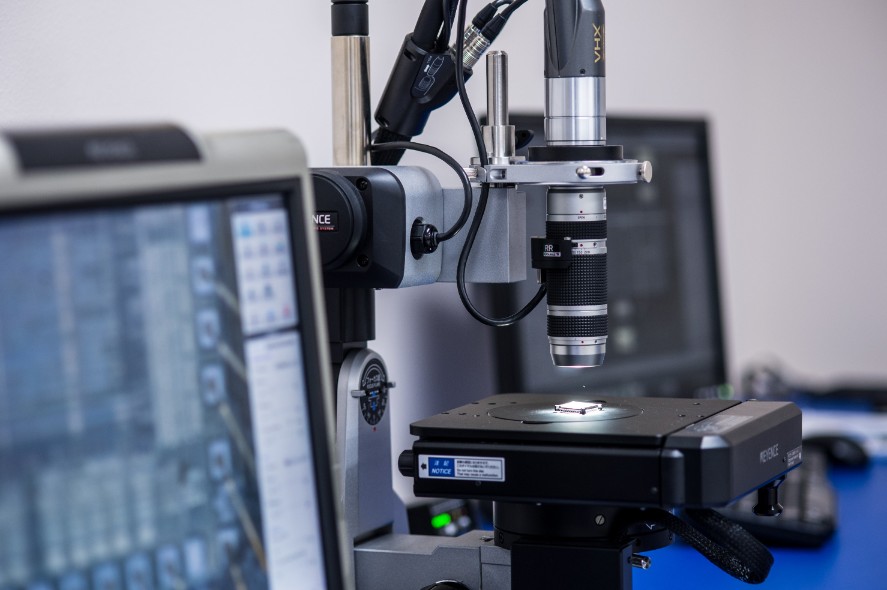

High-Power Microscopy

Marking Permanency

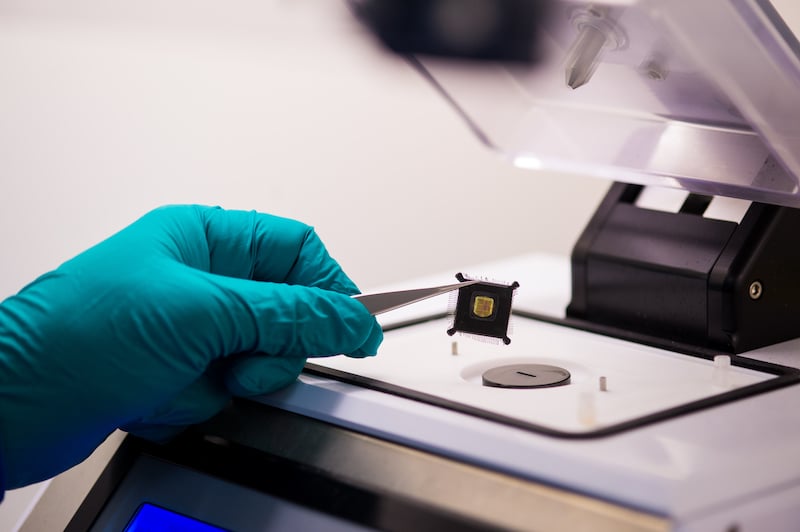

X-Ray Signature Analysis

Decapsulation/Delidding

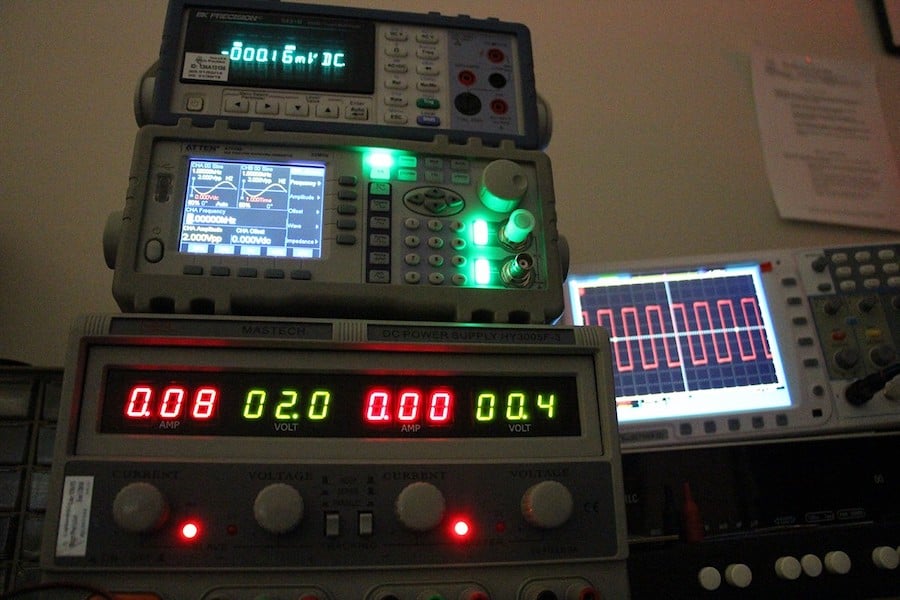

Low Power Electrical

BGA & QFN Analysis

Heated Solvents Analysis

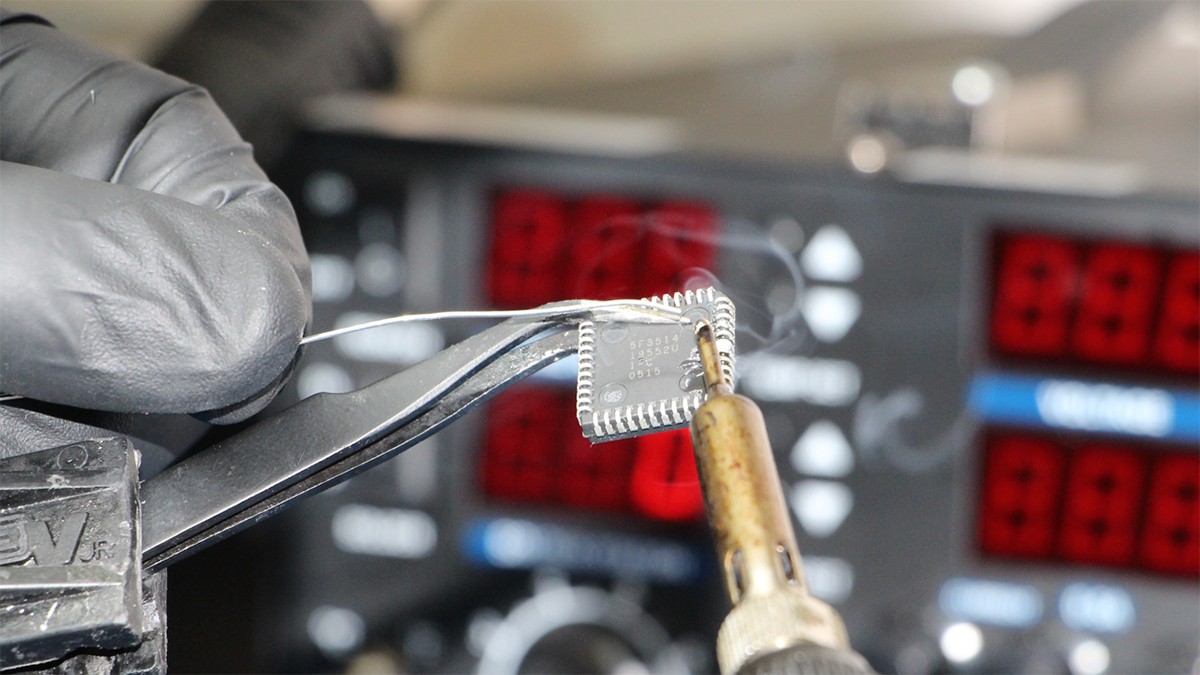

Solderability Screening

XRF Analysis

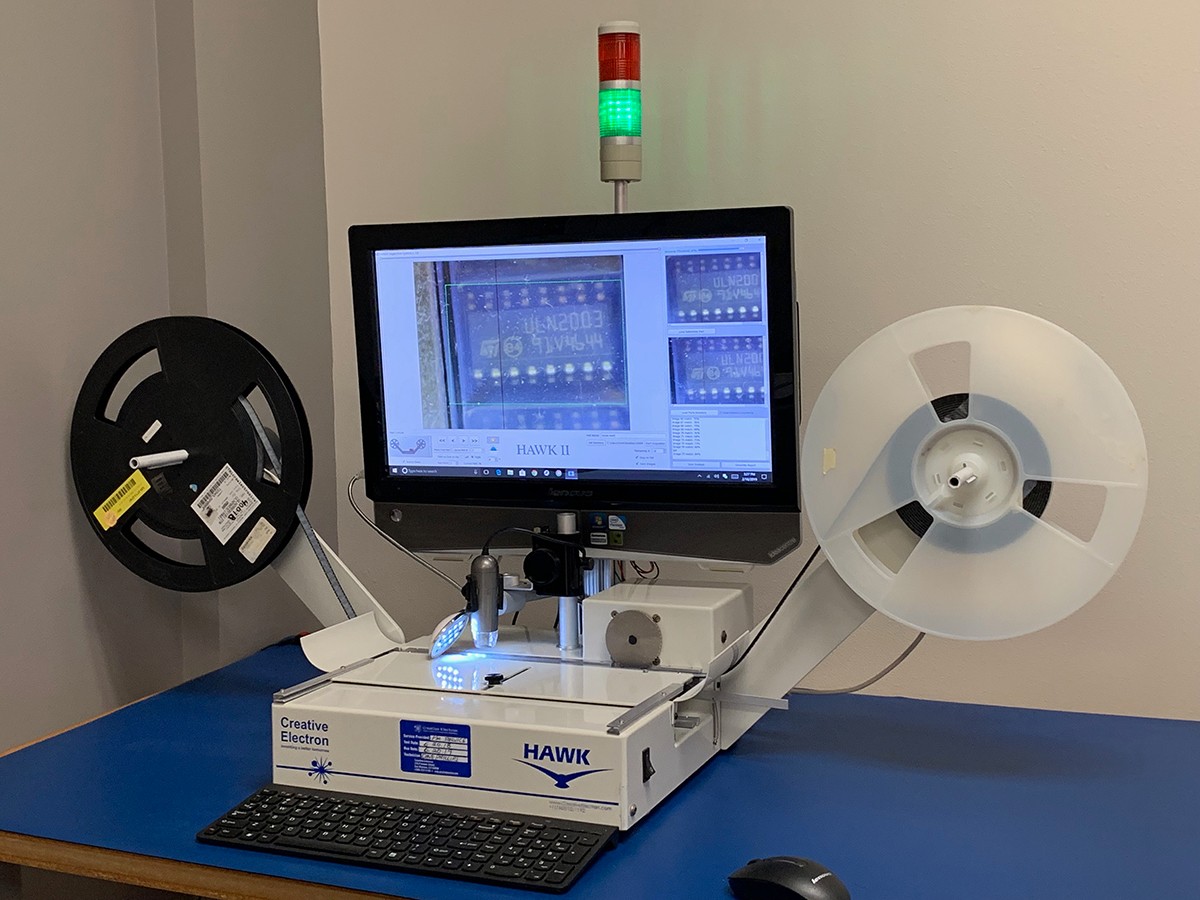

Automated Reel to Reel

Curve Trace Analysis

Moisture Baking

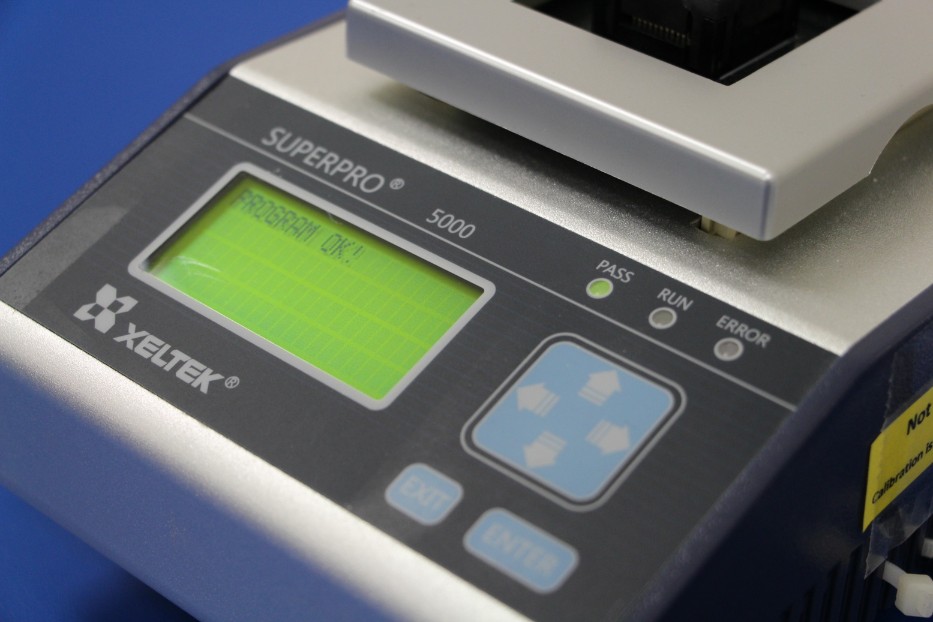

Programming

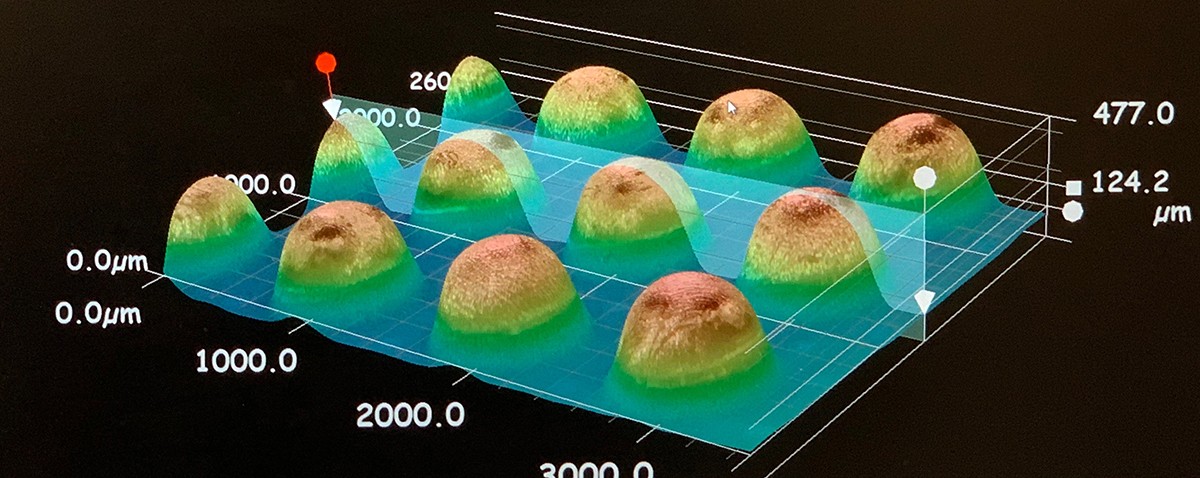

3D Imaging

Why Choose Sensible Micro for Testing & Inspection?

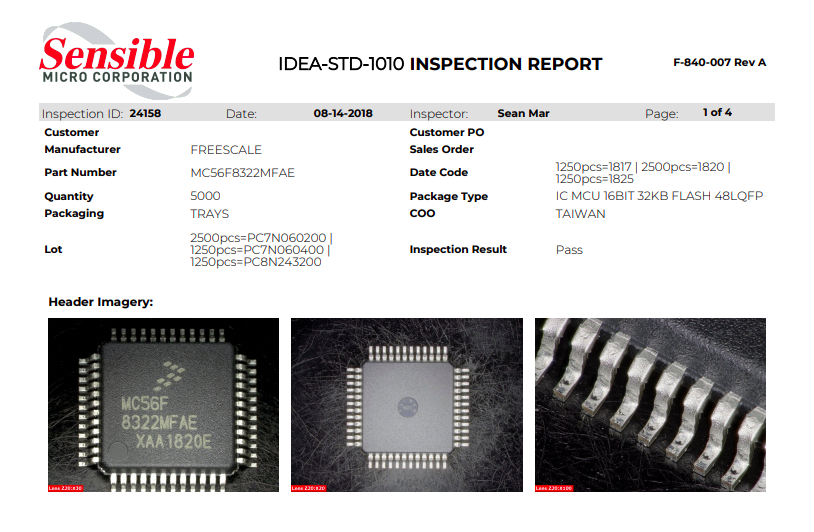

Our inspection standards are among the industry’s best. It all starts with our IDEA-STD-1010-B visual inspection processes, administered only by IDEA-ICE-3000 certified inspectors and proven to be an effective visual inspection protocol, cited in AS5553 and used by the most quality-focused OEMs and distributors in the industry.

Request a Sample Report

Our customers are able to log in to a personal portal to view electronic component test reports with hi-res images, order tracking details, and more.

Wondering what a visual inspection or lab report looks like?

Building Customer Confidence Through Testing

Sensible Micro has supported countless clients and shipped hundreds of millions of parts with the aid of our testing and inspection services.

We’re proud to help you avoid costly errors and build products that consumers trust. Our results speak for themselves, with a high retention rate and a reputation for excellence.

WE'D LOVE TO HEAR FROM YOU

Connect With Us

Reach out to request a quote or learn more about our electronic components sourcing and supply chain solutions.